I-PVC Converor Belt: Isixazululo esiguquguqukayo sokuphathwa kahle kwezinto ezibonakalayo

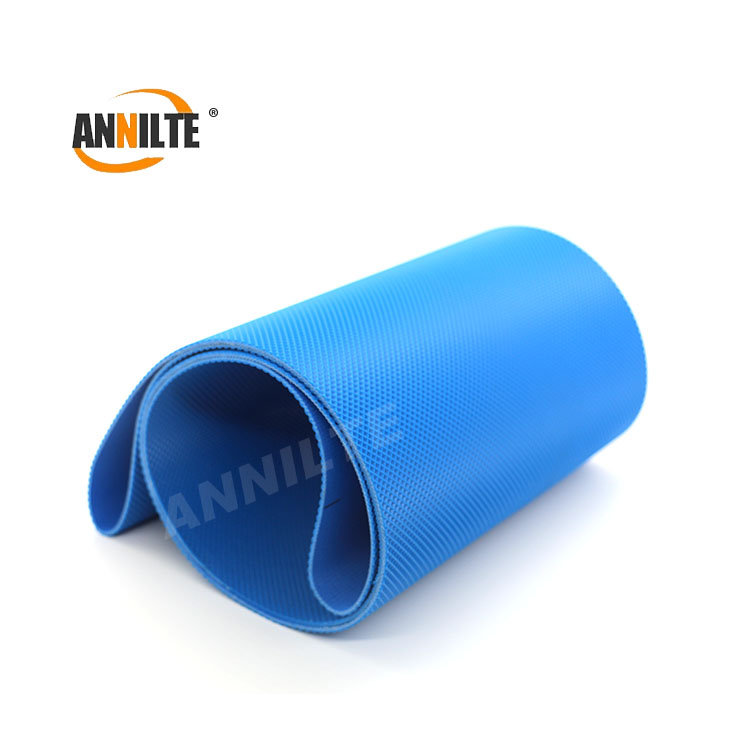

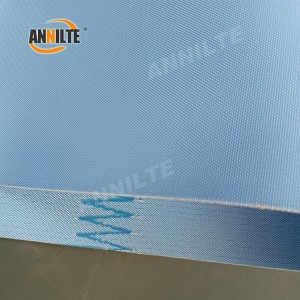

Uhlobo lwenhlanziIsikhombisi sebhandeKwenziwa kusuka ezintweni zokwenziwa zepulasitiki ezaziwa ngokuthi i-polyvinyl chloride. Lokhu okuqukethwe kudume ngokuqina kwawo, ukuvumelana nezimo kanye nokumelana nokugqoka nokudabula. Uhlobo lwenhlanziIsikhombisi sebhandeAma-Pers amaningi, ngalinye lifaka isandla emandleni nasekusebenzeni kweBelt jikelele. Ungqimba olungaphezulu, olwaziwa kakhulu njengesembozo, luhlinzeka ngokuvikelwa ezintweni zangaphandle ezinjenge-abrasion, amakhemikhali, nokuhluka kokushisa. Izendlalelo eziphakathi zinikeza amandla nokuqina, kanti ungqimba olungezansi lunikeza ukuqina okungeziwe nokuvumelana nezimo.

Izinzuzo zamabhande e-PVC conveyor

- Ukuqina: Amabhande e-PVC athuthele enzelwe ukumelana nemithwalo esindayo, ukusetshenziswa njalo, kanye nezindawo ezisebenzayo ezisebenzayo. Ukumelana kwabo ne-abrasion namakhemikhali kuqinisekisa isikhathi sokuphila eside, kunciphisa isidingo sokufakwa kabusha kwezidingo.

- Ukuguquguquka: Lawa mabhande alungele izimboni ezahlukahlukene, kufaka phakathi ukudla neziphuzo, ukupakisha, amakhemikhali, ukukhiqiza, nokuningi. Ukuzinzile kwazo kubenza bavumelane nezicelo ezahlukahlukene, ekuthuthweni kwezinto ezintekenteke ezintende kuya kwezinto ezisindayo zezinqwaba.

- I-HYGIENE NOKUPHEPHA: EMANDLA NJENGOBUCHWEPHESHE NJENGOBUCHWEPHESHE NJENGOBUCHWEPHESHE BOKUFA, Ukuhlanzeka kubalulekile. Amabhande okuhambisa ama-PVC kulula ukuwahlanza futhi alondoloze, okwenza babefanelekela izimboni ezinezidingo ezinzima zokuhlanzeka. Ngokwengeziwe, banikeza indawo engeyona eye-slip ethuthukisa ukuphepha kwabasebenzi ngokuvimbela izingozi ezibangelwa ukuslayida kwezinto ezibonakalayo.

- Ukusebenza kwezindleko: Amabhande e-PVC athutha avame ukungabizi kakhulu kunamabhande enziwe kwezinye izinto ezifana nenjoloba noma insimbi. Izindleko zabo zokuqala eziphansi, ezihambisana nokulungiswa okuncishisiwe kanye nezindleko zokubuyiselwa emuva, kubenza kube yindlela ephumelelayo yamabhizinisi.

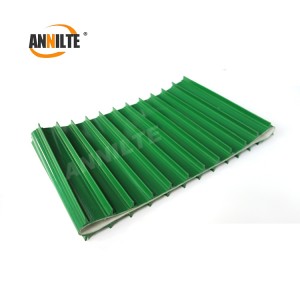

- Ukwenza ngokwezifiso: Amabhande e-PVC athutha angenziwa ngobubanzi obuhlukahlukene, ubude, kanye nokucushwa ukuze avumelane nezidingo ezithile. Futhi zingadalelwa ngezici ezikhethekile ezifana nama-cleats, ama-useWall, kanye nemihlahlandlela yokulandela umkhondo ukukhulisa ukusebenza kwawo.

- Ukufakwa kalula: Amabhande e-PVC athutha alulaphekile alula futhi avumelana nezimo, awenze kube lula ukufaka futhi ukufaka esikhundleni. Lesi sici sinciphisa isikhathi sokuphumula ngesikhathi sokufakwa noma imisebenzi yesondlo.

Izicelo ze-PVC Converor Belts

- Imboni yokudla: Amabhande okuhambisa i-PVC asetshenziswa kabanzi embonini yokudla yokuhambisa izinto ezifana nezimpahla ezibhakiwe, izithelo, imifino kanye nenyama. Izakhiwo zabo zokuhlanzeka, ukumelana namafutha namafutha, kanye nokuhambisana nemithetho yezokuphepha yokudla kubenze kube yinto ethandwayo.

- Imboni yokupakisha: Lawa mabhande enza lula ukunyakaza okubushelelezi kwemikhiqizo ehlanganisiwe, iziqukathi namabhokisi ngesikhathi senqubo yokupakisha. Ukuqina kwabo kanye nokumelana kwabo nemiphetho ebukhali nokuhlukumezeka kuqinisekisa ukusebenza okuthembekile.

- Imboni yezimoto: Amabhande e-PVC athuthele aqashwa ekwenzeni izimoto ezenzakalweni njengezinqubo zomugqa womhlangano, ukuphatha izinto, kanye nezinto zokuhambisa ngaphakathi kwesendaweni yokukhiqiza.

- Imboni yezemithi: Ekukhiqizweni kwemithi, ukucacisa nokuhlanzeka kubalulekile. Amabhande e-PVC Converor asiza ukugcina ubuqotho bemikhiqizo ngenkathi benamathela kulayini amazinga okuhlanzeka aqinile.

- Ukugcinwa kanye nokusatshalaliswa: Amabhande e-PVC athutha asetshenziswa ezikhungweni zokuhambisa kanye nama-reving