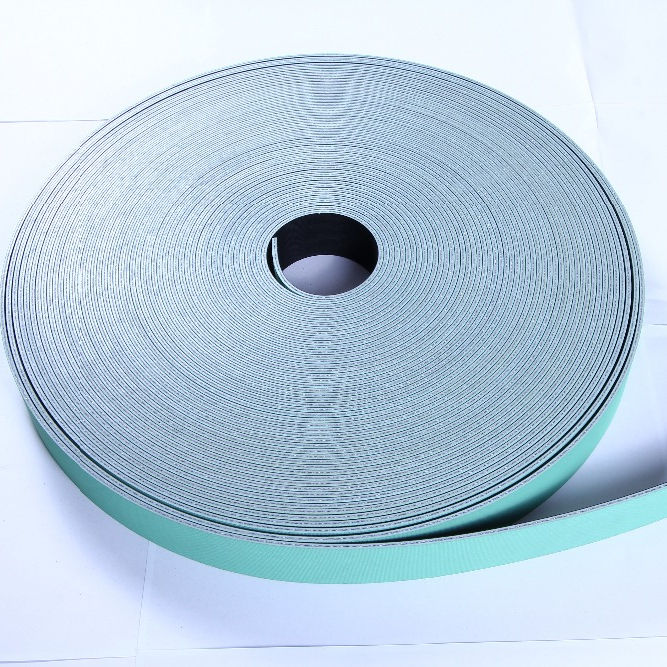

Ngokudluliswa kwemishini okuvumelana nezimo, umsebenzi ongenamsebenzi omncane osetshenziswayo ohlelweni lokudluliswa kwamandla, kuba ngcono umphumela wokonga amandla. Ngenqubo yokudlulisa amandla ebhande eliyisicaba elivamile, isisindo somzimba webhande, indawo esongwe ngobubanzi besondo namandla okunwetshwa okugxilile anquma ukusetshenziswa kwamandla omzimba webhande lapho kwenziwa umsebenzi. Ngakho-ke, ukukhethwa nokucushwa kwebhande lokudlulisela emishinini kuyisici esibalulekile sokuthuthukisa ukonga amandla, futhi ibhande lokudlulisela eline-elongation eqinile, umzimba webhande elithambile kanye nokungqubuzana kwendawo okuphakathi kuyisinqumo esingcono kakhulu kumakhasimende.Ibhande le-polyester drive lika-Annilte lizixazulula kahle izinkinga ezingenhla.

1. I-polyester enezici zokonga amandla

a) Amandla okuqina aphezulu kanye nokushuba okuzinzile.

Ngokuvamile, uma kuqhathaniswa ne-substrate, amandla angu-1% agxilile webhande le-polyester aphakeme ngo-30% kuya ku-50%, okusho ukuthi ibhande alidingi ukulungisa ukungezwani ngokuphindaphindiwe ngemva kokulungisa amandla okucindezela. Ngaphezu kwalokho, ukusebenza kwayo okubushelelezi, ukungezwani okulinganiselwe futhi akulula ukulahlekelwa isivinini, ukuze umthwalo othwala uncishisiwe, ngaleyo ndlela ulondoloze ukusetshenziswa kukagesi.

b) Izintambo zinesisindo esincane

Ungqimba oluqinile lwebhande le-polyester luyisakhiwo esikhethekile sendwangu ye-polyester enezinga eliphezulu eliphansi, lapho ukudluliswa kwamandla okufanayo, ungakhetha ibhande elincane elincane, ukuze unciphise umzuzu we-inertia kanye namandla we-centrifugal webhande eliyisicaba, ukuze ukusetshenziswa kwayo kwamandla kuncishiswe futhi kugcinwe ukusetshenziswa kukagesi.

c) Ukuvumelana nezimo okuhle

Ngenxa yokuthi umzimba webhande le-polyester uthambile, umzimba webhande nesondo lebhande kusongwe kahle, ingcindezi yokugoba iyancishiswa, ukusebenza kahle kokudlulisela kuyathuthukiswa futhi ukusetshenziswa kwamandla kugcinwa ngokulingana.

d) Isixhumi siyashesha futhi sihambisana nemvelo

Ijoyinti lithatha isibopho sezinyo elincibilikayo elishisayo lomzimba we-thermoplastic elastomer, akukho okunamathelayo okufakwayo, futhi ukusebenza akukhawulelwe lapho kuya ngakhona, ngakho-ke isikhathi sokufakwa siyagcinwa futhi ukungcoliswa kwemvelo kuyehla.

2. Umphumela wokonga amandla

Ukuhlolwa kokuqhathaniswa kwenkundla kukhombisa ukuthi isilinganiso sokonga amandla esicucu se-polyester singaphezulu kuka-10% kuneso le-baseband yasekhaya neyangaphandle.

Umphumela wokonga amandla webhande le-polyester ubaluleke kakhulu, emshinini wezintambo zokumboza, izinga lokonga amandla lingafinyelela ku-20%, emshinini omfushane wokusonta i-fiber kabili, izinga lokonga amandla lingaphezu kuka-15%, emshinini wokusonta izikhathi ezingu-310, izinga lokonga amandla liyi-10%. Ngakho-ke, ibhande le-polyester elinomsebenzi walo omuhle kakhulu wokonga amandla, selisetshenziswe kabanzi njengebhande likadrako kanye nebhande lamandla lemishini emisha enesivinini esikhulu njengomshini wokumboza intambo, umshini wokuphotha omude kakhulu, umshini wokuphotha ojikelezayo kanye nomshini wokusonta kabili.

3. Ukuqhathaniswa kokusebenza kwesakhiwo

Ibhande le-polyester lenziwe ngerabha ekhethekile yokwenziwa ye-carboxyl nitrile butadiene njengento eyinhloko yongqimba lokushayela nokushayisana, futhi ukusebenza kuyafana nalokho kwe-substrate.

Ishidi le-thermoplastic polymer elastomer lisetshenziswa njengesendlalelo soguquko esiyinhlanganisela. Ngemuva kokoma, izinhlayiya ze-polymer ezishisayo ziyancibilika futhi zikhishwe yi-extruder ukuze zakhe ishidi elinobukhulu obufanayo nobubanzi obuyi-1200mm. Futhi ngokusho kobukhulu obuhlukile bebhande lomzimba elibunjwayo 0.3 ~ 1.2mm ukujiya okuhlukile kwemikhiqizo yeshidi. Indaba inezici zokunwebeka okuhle kakhulu, ukumelana nowoyela, ukumelana nezinga lokushisa, ukumelana nokukhathala, ukuguquguquka, amandla adonsela phansi amancane kanye nesisindo esilula, futhi inezakhiwo ezinhle zokubopha ezinongqimba oluqinile nerabha.

Isikhathi sokuthumela: Nov-30-2023